2020-04-22

Initial Situation

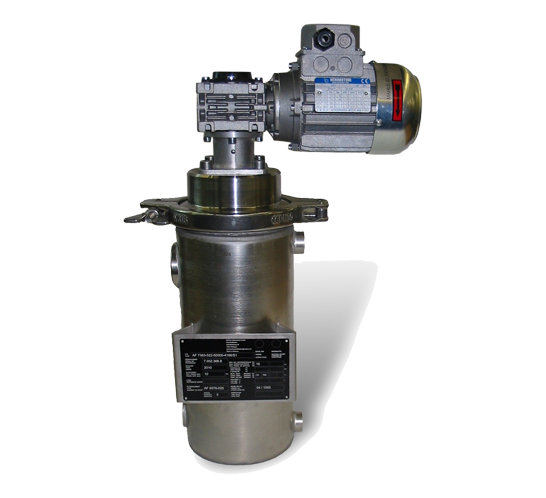

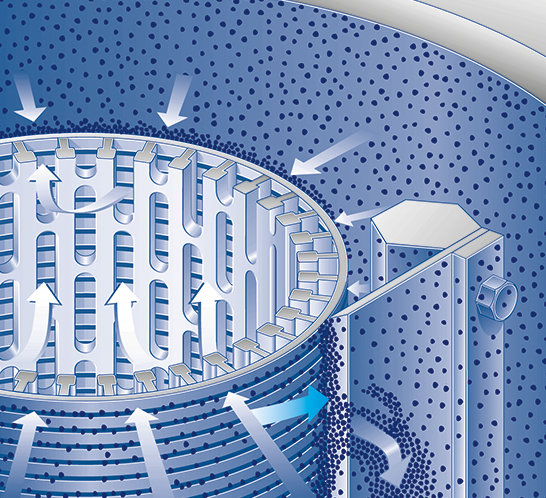

Our customer is one of the largest and most modern plants for the production of shell ice cream, stick ice cream and wafer croissants. In the production and filling process of walnut ice cream a constant homogeneous quantity of walnut pieces is required. In the starting process, a certain amount of waste is produced until the concentration has reached the desired level. The offcuts cannot be used any further. In order to be able to reuse the ice cream mass and the walnut pieces, both products must be separated from each other so that they can be used again.

Challenge

The industrial production of ice cream is carried out in closed systems to ensure a particularly high level of hygiene protection. The raw materials are balanced and premixed according to a recipe prescribed for the individual types and flavours. This produces the so-called premix. The homogenizer breaks down the premix under high pressure through a sieve into small, fine components. This allows the milk fat to be distributed evenly and the ice cream contains a smooth, creamy melt. The ice cream mass is then pasteurised. It is heated briefly to 75 °C and then cooled down to 4 °C to prevent undesirable microorganisms from surviving in the ice cream mix or from forming again afterwards. The ice cream must then mature in refrigerated containers to develop its full aroma. In the so-called freezer, the ice cream is finally given its final composition.

Technical Data

Solution

Customer Value