2019-10-14

Initial Situation

A well-known manufacturer of Diesel-systems produces in Homburg/Saar among others fuel injection pumps for passenger cars. The components are produced on different machine centers. In the molding machines oil is mainly used as cooling lubricant for the tools. Due to the high rotary speeds the oil evaporates in working room of the machine centers. The oil mist needs to be evacuated from the machine and the employees need to be protected against breathing in the harmful oil aerosols.

Challenge

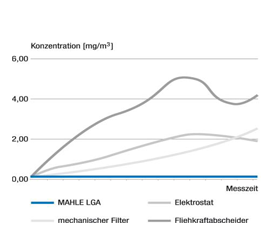

At the machine centers of the manufacturer there are generally electrostatic-separation systems installed. The air together with the oil mist is evacuated from the machine working room, but the separation result was not satisfactorily.

The problems are, that oil drops deposit in the factory hall and on the machines, machine operators and other employees have to breath in harmful oil aerosols and the maintenance intervals for electrostatic separation systems are very short.

The target is to increase the separation rate and significantly reduce remaining oil content in the air. Further topics are the compliance with the prescribed values of the « TA-Luft », reliable comlete solution with low maintenance requirements and assured protection of employees and equipment.

Solution

The Filtration Group LGA oil-mist separators have been installed, piped, configured and launched on multiple machine centers by the Filtration Group service engineers. A significant increase of the separation rate was achieved and documented. Further results are a secured separation and recovery even of finest oil droplets by the nearly maintenance free coalescer principle and the protection of employees and equipment thanks to the compliance to prescribed TA-Luft values.

Customer Value

Customer advantages are an extension of the service interval from 3 to 12 month, reduction of machine downtime to a necessary minimum and a reliable protection of the employees` health. With our LGA, we offer a complete recovery of the separated oil and nearly no wasted material in the LGA-system. The issue of intensive cleaning efforts for the removal of oil films in the production hall and in the machine centers has been eliminated completely.