Wind Power

Filter systems for an optimal energy balance

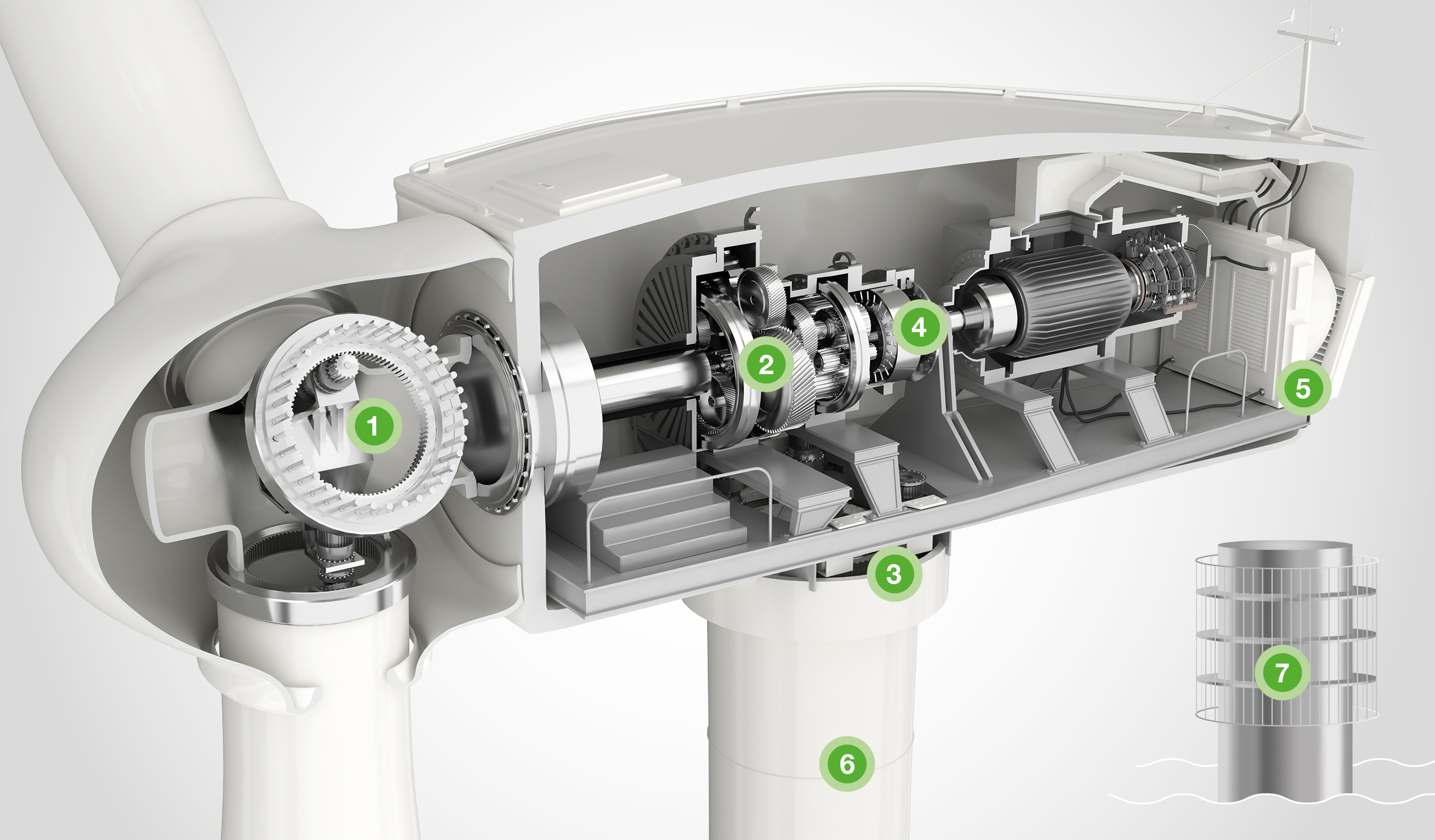

A wind turbine is only profitable if the rotors rotate and the turbine starts to generate electricity. Various filtration systems from Filtration Group clean the air, the lubricating oil and the water in the Nacelle to which the turbine is attached, in the tower and in the transformer platform in order to meet the requirements of weather conditions, technology and environmental protection.

Medium and high pressure filters in the brake system, in the azimuth drive and in the pitch system clean the lubricating oils, ventilation filters and the ambient air sucked in from dirt particles and dust. In the Nacelle and in the tower, air conditioning systems, so-called conditioning units, ensure that sensitive control units do not overheat during operation. For fuel processing and to prevent contaminated water from getting into the environment, oil separators, fuel processing systems and sea water filters are used in the transformer platform, the functioning of which is based on the principle of separation.

Together we are making wind power…

…safer, because we help you to avoid malfunctions and prevent failures of control elements

…healthier, because our products meet the preconditions for acquiring energy from a regenerative source both on land and on the open sea and under hostile weather conditions

…more productive, because we ensure smooth operation of the wind power system.

Applications

Filtration Group makes the core of wind energy clean

On the high seas or in the middle of the pampas, wind turbines are constantly exposed to the weather. Their smooth functionality even under adverse circumstances is the basic requirement that enable electricity to be generated from wind. Filtration Group’s filter systems remove dirt particles from the air, operating fluids or surface water that can impair the efficient functioning of the system.

Contact

We’re happy to help.

Just contact us.

Special solutions

Filtration Group also offers all filter systems and separation plants as tailor-made solutions. Our experts will be happy to advise you which variant best suits the special requirements of your working environment.