Hydraulic Filtration

Efficient filter systems for hydraulic systems

Filtration Group Industrial filters increase the life and performance capacity of hydraulic systems by providing maximum fluid cleanliness. Innovative materials and technologies such as e-protect or PulseShieldTM permanently protect machinery and equipment against soiling and premature wear. Because the filtration systems are ruggedly built and equipped with high-quality filter media, FGI hydraulic filters withstand high pressure and rarely require maintenance. In addition to a large selection of original filter systems, Filtration Group Industrial also offers the high-quality filter elements as EcoParts for filter systems from other manufacturers.

Designed for use as a full or partial flow filter and for low pressure up to 25/60 bar, medium pressure up to 210 bar and high pressure up to 450 bar, Filtration Group pressure filters are precisely tailored to the requirements of the application as line filters, flange filters and filters in sandwich plate design. Robust housings, flow optimized design and a comprehensive accessory program always offer the right solution for all market requirements.

Designed for use as a full or partial flow filter and for low pressure up to 25/60 bar, medium pressure up to 210 bar and high pressure up to 450 bar, Filtration Group pressure filters are precisely tailored to the requirements of the application as line filters, flange filters and filters in sandwich plate design. Robust housings, flow optimized design and a comprehensive accessory program always offer the right solution for all market requirements.

LOW PRESSURE FILTERS

- Pi 1907, PN 10/16 bar, size 400-6000

- Pi 1975, PN 6 bar, size 50

- Pi 200, PN 32/63 bar, up to size 600

- Pi 2000, PN 25/63 bar, size 40-400, according to DIN 24550

- Pi 220, PN 10/25 bar, size 25-160

- Pi 260, PN 25 bar, up to size 1100

- Pi 270, PN 10 bar, size 250-315

MEDIUM PRESSURE FILTER

- Pi 3000, NP 210/315 bar, size 40-400, according to DIN 24550

- Pi 340, NP 250/315/350 bar, size 50-450

- Pi 3400, NP 250/315/350 bar, size 40-400, according to DIN 24550

- Pi 344, NP 315, size 700 and 100

- Pi 360, NP 210/315 bar, size 50-450

HIGH PRESSURE FILTERS

Duplex filters allow a filter change during live operation and are thus suitable for use in motors and drives that have to reliably run continuously. Thanks to the compact design, duplex filters require little space and have a low flow resistance.

Duplex filters allow a filter change during live operation and are thus suitable for use in motors and drives that have to reliably run continuously. Thanks to the compact design, duplex filters require little space and have a low flow resistance.

LOW PRESSURE DUPLEX FILTERS

- Pi 210 / Pi 212, PN 32/63 bar, up to size 600

- Pi 214, PN 100/160 bar, size 300

- Pi 2100, PN 25/63 bar, size 40-400, according to DIN 24550

- Pi 2110, PN 40 bar, size 630+1000, according to DIN 24550

MEDIUM PRESSURE DUPLEX FILTERS

Whether installed in front of the pump or, for greater maintenance-friendliness, installed with maintenance indicator in the suction line for easy access from outside, they protect the pump from course impurities. With a wide range of system-compatible elements, the protection of systems and pumps in the fine range of 10 – 25 μm can be guaranteed with our MIC medias or in the coarse range with cleanable wire mesh.

Whether installed in front of the pump or, for greater maintenance-friendliness, installed with maintenance indicator in the suction line for easy access from outside, they protect the pump from course impurities. With a wide range of system-compatible elements, the protection of systems and pumps in the fine range of 10 – 25 μm can be guaranteed with our MIC medias or in the coarse range with cleanable wire mesh.

PRODUCT INFORMATION

All impurities generated in the system and flushed from the hydraulic system are collected by the return line filter, thereby preventing the development of a cycle of contamination through the tank and pump.

All impurities generated in the system and flushed from the hydraulic system are collected by the return line filter, thereby preventing the development of a cycle of contamination through the tank and pump.

PRODUCT INFORMATION

Corrosion and impact-resistance breather filters are used for impurity-free air supply of tanks. A large selection of system-compatible, changeable filter elements secures the required compatibility with the filter fineness of the hydraulic filters.

Corrosion and impact-resistance breather filters are used for impurity-free air supply of tanks. A large selection of system-compatible, changeable filter elements secures the required compatibility with the filter fineness of the hydraulic filters.

PRODUCT INFORMATION

Oil filter module Pi 8300 for use in the primary flow

Oil filter module Pi 8300 for use in the primary flow

For gear oil filtration (primary and bypass flow) and for lubrication systems in wind turbines, Filtration Group Industrial has developed an innovative, compact oil filter module that increases and sustains the efficiency and service life of the hydraulic and transmission units. The system consists of a filter block with electric motor, gear pump, filter housing with highly efficient 2-stage filter element, pressure relief valve, non-return valve and maintenance indicator. It is available in two version with 110 l/min and 220 l/min volumetric flow. As a complete system in conjunction with an oil cooler, the oil filter module Pi 83116 ensures optimal filtration and cooling of wind power gearboxes and enables low-wear and maintenance-friendly operation.

Datasheets

Oil filter module Pi 8400 for use in bypass filtration

The newly developed filter module sets new standards in off-line filtration and is compatible with the previously used compact systems. The water-absorbing premium filter elements with PulseShieldTM technology filter with a fineness of 3 μm. They reliably separate even finest particles and oil aging products (varnish).

Datasheets

The use of filter elements can only be economically optimal when their dirt holding capacity can be fully utilized without risk. Mechanical or electronic sensors integrated in the filters or installed later respond to continuous changes in the pressure conditions that vary by contamination level and indicate them either via manometer or optical and optical-electrical switches, depending on design. With suction filters, low pressure is registered, while with pressure filters differential pressure is registered and with return line filters the dynamic pressure is registered. The operator can determine the optimal time for changing the filter elements without risk.

The use of filter elements can only be economically optimal when their dirt holding capacity can be fully utilized without risk. Mechanical or electronic sensors integrated in the filters or installed later respond to continuous changes in the pressure conditions that vary by contamination level and indicate them either via manometer or optical and optical-electrical switches, depending on design. With suction filters, low pressure is registered, while with pressure filters differential pressure is registered and with return line filters the dynamic pressure is registered. The operator can determine the optimal time for changing the filter elements without risk.

PRODUCT INFORMATION

Always specifically tailored to the required purity class, the pressure conditions and the properties of the medium, Filtration Group’s stable and differential pressure-resistant filter elements ensure trouble-free and economical operation with a high level of dirt-holding capacity. In our comprehensive program of standard and DIN designs, you will also find alternate versions for virtually any filter brands, as well as filter elements for aggressive fluids, cooling lubricants and aqueous media.

Always specifically tailored to the required purity class, the pressure conditions and the properties of the medium, Filtration Group’s stable and differential pressure-resistant filter elements ensure trouble-free and economical operation with a high level of dirt-holding capacity. In our comprehensive program of standard and DIN designs, you will also find alternate versions for virtually any filter brands, as well as filter elements for aggressive fluids, cooling lubricants and aqueous media.

Upon request, we also develop special customer-specific versions.

DATASHEETS

When it comes to replacement requirements for filter elements for stationary and mobile hydraulic systems, a level of quality is required that meets all requirements efficiently and is also economical. Filtration Group offers a complete program of filter elements for hydraulic applications for reliable and economical replacement.

When it comes to replacement requirements for filter elements for stationary and mobile hydraulic systems, a level of quality is required that meets all requirements efficiently and is also economical. Filtration Group offers a complete program of filter elements for hydraulic applications for reliable and economical replacement.

The benefits for you:

- A large product range of pressure filter elements and return line filter elements from a single source – in many different designs and efficiencies

- Compatibility with many common manufacturers (Cross Referencing

- Specified filter output and purification class

- Specified service life

- High functionality and safety

- High reliability and efficiency

- Certified quality

- Tested for compliance with DIN and ISO standards with all applicable industry certifications

Our filters reduce solid contamination to the specified contamination class, prevent the penetration of dirt from the environment and maintain the properties of hydraulic fluid over time.

Further product information on our EcoParts series can be found in our online-shop.

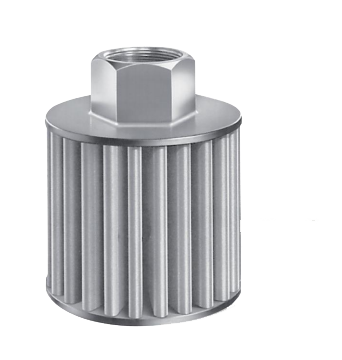

We offer a wide assortment of spin-on cartridges for hydraulic and lubricating oil filtration. For Filtration Group Industrial spin-on cartridges, both conventional cellulose filter media as well as wire mesh and premium fiber glass media are used.

We offer a wide assortment of spin-on cartridges for hydraulic and lubricating oil filtration. For Filtration Group Industrial spin-on cartridges, both conventional cellulose filter media as well as wire mesh and premium fiber glass media are used.

This ensures that the appropriate filtration solution is designed for any application and customer requirement.

Spin-on cartridges with fiberglass media are “long-life” easy-change filters and offer the advantages of our renowned hydraulic elements with the multi-layer design.

Compared to competitors, our “long-life” Spin on Cartridges have an up to 30% longer service life with equivalent filtration efficiency

Spin-on cartridges from Filtration Group Industrial are available in different designs, dimensions and pressure levels.

PRODUCT INFORMATION

Coalescer filters were specially designed for removing water from hydraulic systems. They run cost-effectively and easily without absorbents: Specially configured filter media collect the small water droplets suspended in the fluid and separate them.

Coalescer filters were specially designed for removing water from hydraulic systems. They run cost-effectively and easily without absorbents: Specially configured filter media collect the small water droplets suspended in the fluid and separate them.

DATASHEETS

Released Parts List Mechanics

For the foundry of the Volkswagen Group

Download PDF Components-Foundry

Released Parts List Mechanics

for the production of the engine, gearbox, chassis, and foundry of the Volkswagen Group

Special solutions

Filtration Group offers all filter systems and separation systems as customized solutions. Our experts will be happy to work with you to find the version that best meets the specialized requirements in your work environment.