Separation

Powerful systems for treatment and conditioning

Separation systems from Filtration Group Industrial ensure clean treatment of oil, fuel, bilge and surface water in many applications. The separation of contaminated liquids works according to the proven coalescer principle, which does not require the use of additional chemicals and is nevertheless very efficient. Combined with a comprehensive service, Filtration Group Industrial offers tailor-made solutions for the shipping, wind energy and industrial applications.

Fuel

High-performance fuel filters and treatment systems from Filtration Group Industrial can make the worst quality fuels optimally usable. Complete fuel filter systems are specially matched to the requirements of large engines. The filter systems work reliably and safely around the clock in fully automated mode. Using the FGI filter and coalescer technology, FGI fuel treatment systems can reduce the water content in fuel to a minimum, and thus prevent premature wear of engine components.

Oil

Filter systems from Filtration Group Industrial for lubricant treatment and lubricant conditioning ensure low-maintenance, trouble-free engine operation over a long period of time. All oil care systems are adapted to your specific area of application, quality and design. Typical contaminations such as solid and suspended particles, sediment, rust and water from the lubricants of all engines. FGI lubricant filters are available as switchable or automatic systems and ensure high availability of your engines.

Bilge water

Bilge water is generated by leakages, during the dewatering of settling and sludge tanks, and by the runoff from various cleaning processes. These contaminants and pollutants must not be allowed to enter seawater under any circumstances. Filtration Group Industrial is your system partner for individual solutions for bilge water purification and, with the MPS/MF, already has systems in its portfolio today with which you can easily comply with future international environmental standards.

Contact

We’re happy to help.

Just contact us.

Special solutions

Filtration Group offers all filter systems and separation systems as customized solutions. Our experts will be happy to work with you to find the version that best meets the specialized requirements in your work environment.

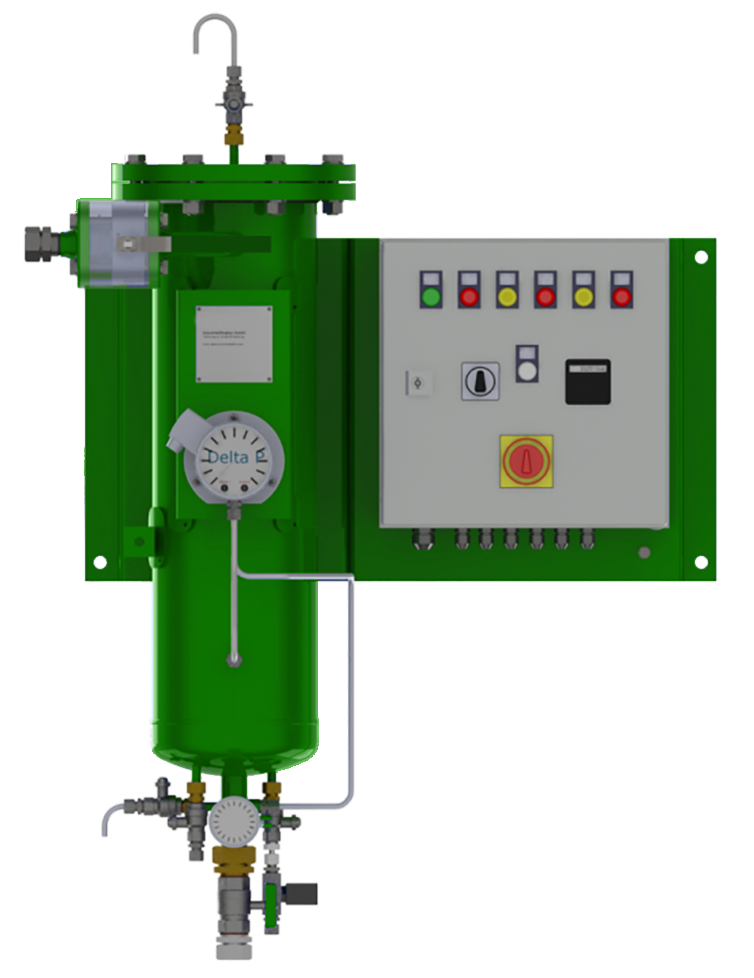

The efficient fuel treatment system prevents concentrations of free water from rising above 70 ppm. It thus acts as an effective protection against the “diesel oil pest”. The single-stage system is used primarily in shipping, preventing engine damage and system failure. Because of its compact design, it takes up little space in the engine room of a ship. However, the fuel treatment system is also perfect for keeping diesel fuel clean in emergency power generators.

The efficient fuel treatment system prevents concentrations of free water from rising above 70 ppm. It thus acts as an effective protection against the “diesel oil pest”. The single-stage system is used primarily in shipping, preventing engine damage and system failure. Because of its compact design, it takes up little space in the engine room of a ship. However, the fuel treatment system is also perfect for keeping diesel fuel clean in emergency power generators.  This two-stage unit filters the fuel as FTS before the water separation in the coalescer elements, which increases the performance and service life of the equipment in case of contamination with larger solid particles. The efficiency of the filters in the first stage can be individually adapted to the medium and requirements. There are potential applications in shipping, industry, in power plants and emergency power generators.

This two-stage unit filters the fuel as FTS before the water separation in the coalescer elements, which increases the performance and service life of the equipment in case of contamination with larger solid particles. The efficiency of the filters in the first stage can be individually adapted to the medium and requirements. There are potential applications in shipping, industry, in power plants and emergency power generators. The PTS is equipped with additional separator membranes in addition to the coalescer elements. These membranes prevent even the finest water droplets from escaping, which means that the fuel or oil is perfectly clean when it comes out. The system is well suited for protection of gas turbines in power plants and for fuel treatment on emergency power units. The PTS is individually configured for the particular requirements.

The PTS is equipped with additional separator membranes in addition to the coalescer elements. These membranes prevent even the finest water droplets from escaping, which means that the fuel or oil is perfectly clean when it comes out. The system is well suited for protection of gas turbines in power plants and for fuel treatment on emergency power units. The PTS is individually configured for the particular requirements.  Coalescer filters were specially designed for removing water from hydraulic systems. They run cost-effectively and easily without absorbents: Specially configured filter media collect the small water droplets suspended in the fluid and separate them.

Coalescer filters were specially designed for removing water from hydraulic systems. They run cost-effectively and easily without absorbents: Specially configured filter media collect the small water droplets suspended in the fluid and separate them. In the version as OFWA, the fuel treatment system is used e.g. for dewatering lubricating oils.

In the version as OFWA, the fuel treatment system is used e.g. for dewatering lubricating oils. With this high-performance system, the residual oil content of the exiting water can be reduced to below 1 ppm. The MPS/MF has a membrane stage downstream to the multiphase separator which separates the remaining water-oil emulsions under high pressure. Oil and other residues are concentrated and recycled.

With this high-performance system, the residual oil content of the exiting water can be reduced to below 1 ppm. The MPS/MF has a membrane stage downstream to the multiphase separator which separates the remaining water-oil emulsions under high pressure. Oil and other residues are concentrated and recycled.