2019-10-14

Initial Situation

High-quality Filtration Group automatic backflushing filters are used in the production of high-performance components for motor sports, tuning and vehicle refinement. Our customer AVL SCHRICK GmbH in Remscheid, manufactures a large selection of high-performance camshafts and drive components for Formula 1, WEC and the American NASCAR series, among others, on ultra-modern combination systems. Different processing steps and technologies are carried out on one machine. AVL SCHRICK uses a FG automatic backflushing filter type R8-40 DN 250 to optimize the production process and increase efficiency.

Challenge

During the grinding process of camshafts and crankshafts, cooling lubricant is injected into the grinding gap at high pressure. Cooling during grinding prevents thermal damage to the components and grinding tools. The process heat is dissipated via a targeted supply of coolant to the machining zone. This high-pressure equipment must be protected by a safe and efficient fine filter stage.

Technical Data

Solution

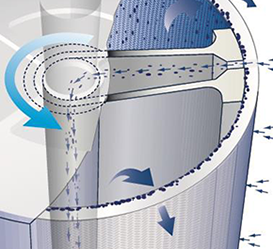

Filtration Group uses a FG automatic backflushing filter type R8-40 DN 250 for this application. The filter avoids clogged nozzles on grinding machines and associated damage to grinding wheels up to machine fire. The filter supplied is used behind an existing filter system consisting of five endless belt filters and complements the decentralized filter concept. The duplex filters on the processing machines are relieved and thus function as police filters and no longer as working filters.

Customer Value

Our backflushing filter offers process reliability of the processig machines, especially in night shift operation, thanks to efficient self-cleaning function through automatic backflushing. Further customer advantages are protection of grinding processes and machine cleaning without filtration interruption, reliable operation without downtime and low space requirement due to compact design.