2019-10-14

Initial Situation

Over the last years thermosolar plants were built in selected regions of the earth to generate energy from sun radiation which can be used to supply thousands of households with power. For instance there is a thermosolar plant in Andalusia with 165.000 parabolic mirrors and a total area of 142 hectare where sun radiation is reflected on a special thermal oil. This oil is heated up to 400°C and flows trough a 74 km long pipe where it is pumped to big heat exchangers. Due to the high temperatures the water vaporizes and is conducted to a central placed 50 MW turbine which produces CO2-neutral power for approx. 43.000 households.

Challenge

Power generated by thermosolar generates a much lower environmental stress than the generation of power with conventional plants. Nevertheless the collected surface water of the plant can be contaminated due to leakages in the oil pipes. As the collected surface water should be used for watering the surrounding fields, it has to be guaranteed that 100% of the contaminations are removed before local farming people can reuse the water. The currently used separation-system was not able to meet the requirements that’s why a Filtration Group separation system is inevitable.

Solution

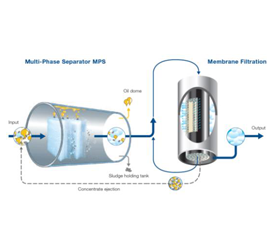

After a series of field tests, Filtration Group decided to install a two-level membrane separation system with a downstream active carbon stage . The system was developed, designed, wired and built on a customer specific frame in the plant in Hamburg. When the MFEB arrived on site the existing pipes were connected and the system was ready-to-operate. Experienced Filtration Group-technicians supported the local workers with all necessary works, until a failure-free operation was accomplished.

Customer Value

Surface water with a high level of contamination (up to 100%) can be treated reliably with the Filtration Group MFEB. The combination of ceramic membranes and activated carbon can separate an oil-water-emulsion without any additional chemicals. A reliable functionality of the system can be guaranteed due to the in years gained experiences in the automotive industry. The residual oil content is < 5ppm which means that the treated water can be used for watering the local fields without any concerns. Further advantages are a long lifetime-span and low maintenance costs.