2020-04-06

Initial Situation

Cooling water systems for removal of surplus heat are found in all sectors. Alongside the standard application cases in thermal power plants and the installations of the chemical indstury, the spectrum of applications spans from machine cooling in the production industry to air-conditioning systems in buildings and the cooling of computer centers. The water used must, on top of chemical stability, have the smallest possible particle load in order to preserve the system components and protect against damages.

Challenge

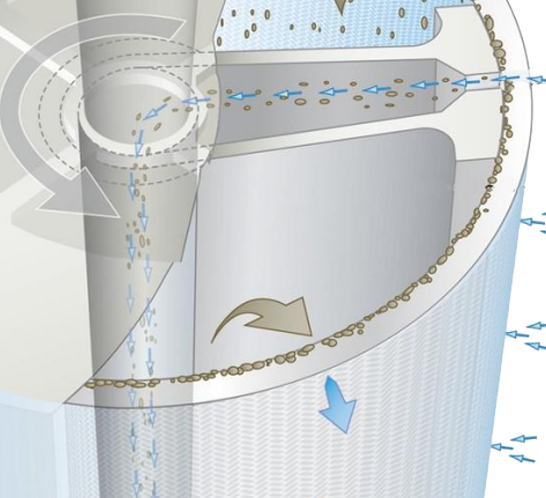

The automatic backflush filter is common as a cooling water filter in a recooling cycle, in which a heat exchanger must be protected from contamination. The undesired particles result from the open or semi-open cooling tower, in which the intake of particles comes from the surrounding air. The particular challenge for cooling water systems is how particles are introduced differently depending on region and season. Alongside the variability of the quantity, it is the qualitative variance of the load in particular that necessitates an especially high-performance and reliable filtration system.

Technical Data

Solution

Customer Value