2020-09-28

FGI Pleated filter elements

Wide selection of high-quality pleated filter elements in conical and cylindrical design or as compact filter elements (CFE™)

Not all dust is the same. Every process is associated with a very specific dust load. A technical as well as economical filter design is a complex task that requires experienced specialists because of the variety of information, data, facets and system parameters to be considered. We offer decades of experience as an innovative development partner and reliable supplier of leading manufacturers. When designing and integrating the appropriate filter system for air pollution control, we guarantee the decisive plus in competence and thus more performance for the filtration process. With dedicated engineering experts, comprehensive application experience and modern tools, we ensure the optimal technical and economic design of filtration technology.

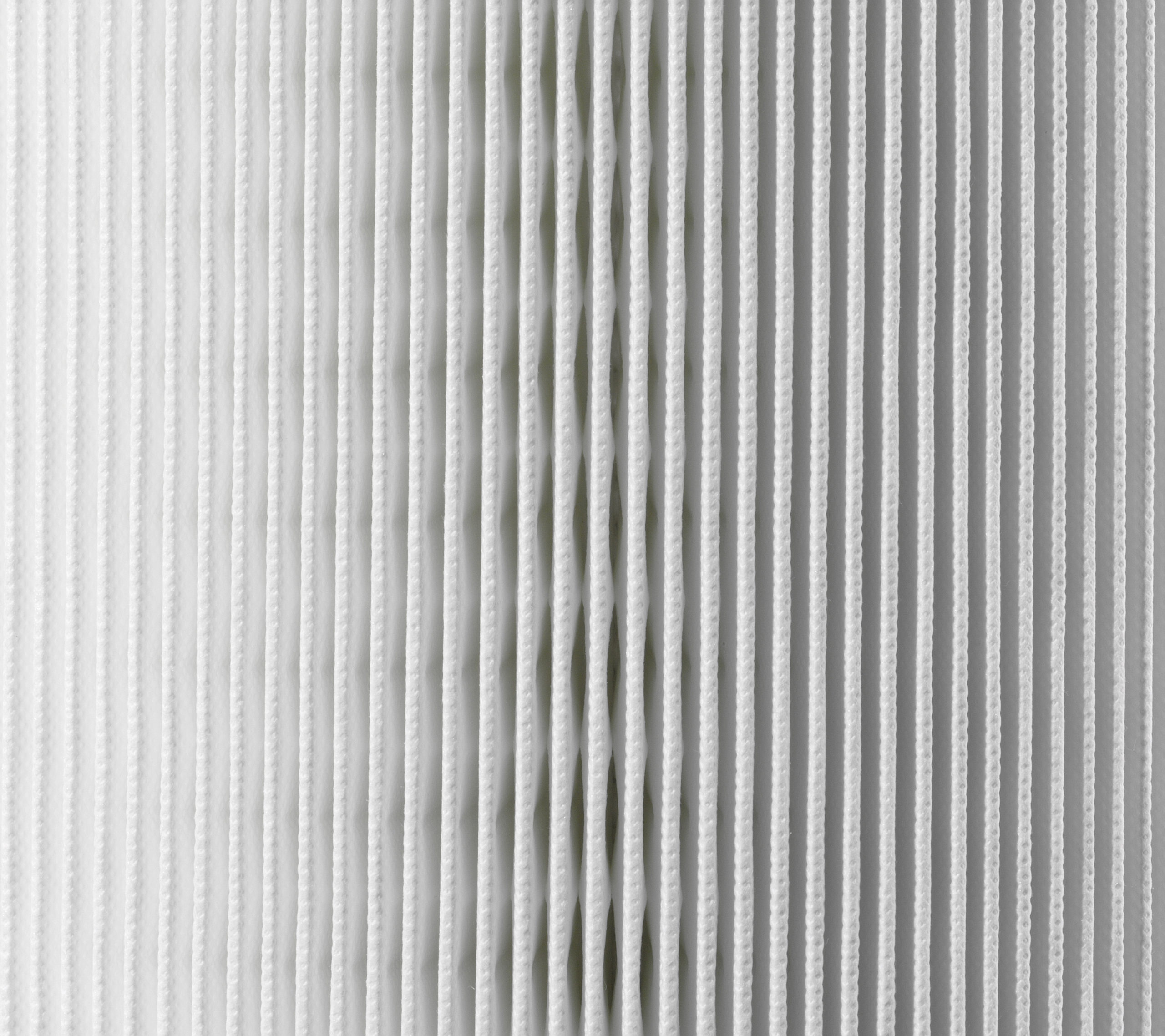

Pleated dust filter elements are used to separate finest particles from gases. The dust-laden gas flows through the filter element from outside to inside and exits through the upper open end plate. The type of filter element as well as the filter material are individually designed to meet the specific requirements of the customer and ensure optimum filtration performance for various applications in the following industries, among others:

To fully meet each individual cleaning performance requirement, Filtration Group Industrial offers high-quality pleated standard filter elements in conical and cylindrical designs. Standard filter elements are available in diameters of 120, 160 and 328 mm and in various lengths with all common mounting systems.

The food and pharmaceutical industry places the highest demands on process quality, purity, plant safety and environmental protection. FGI dust filter elements with the innovative iFix technology are optimally adapted to the specific dust load of your respective process. They guarantee high separation efficiency, economic product recovery and meet all safety and environmental requirements.

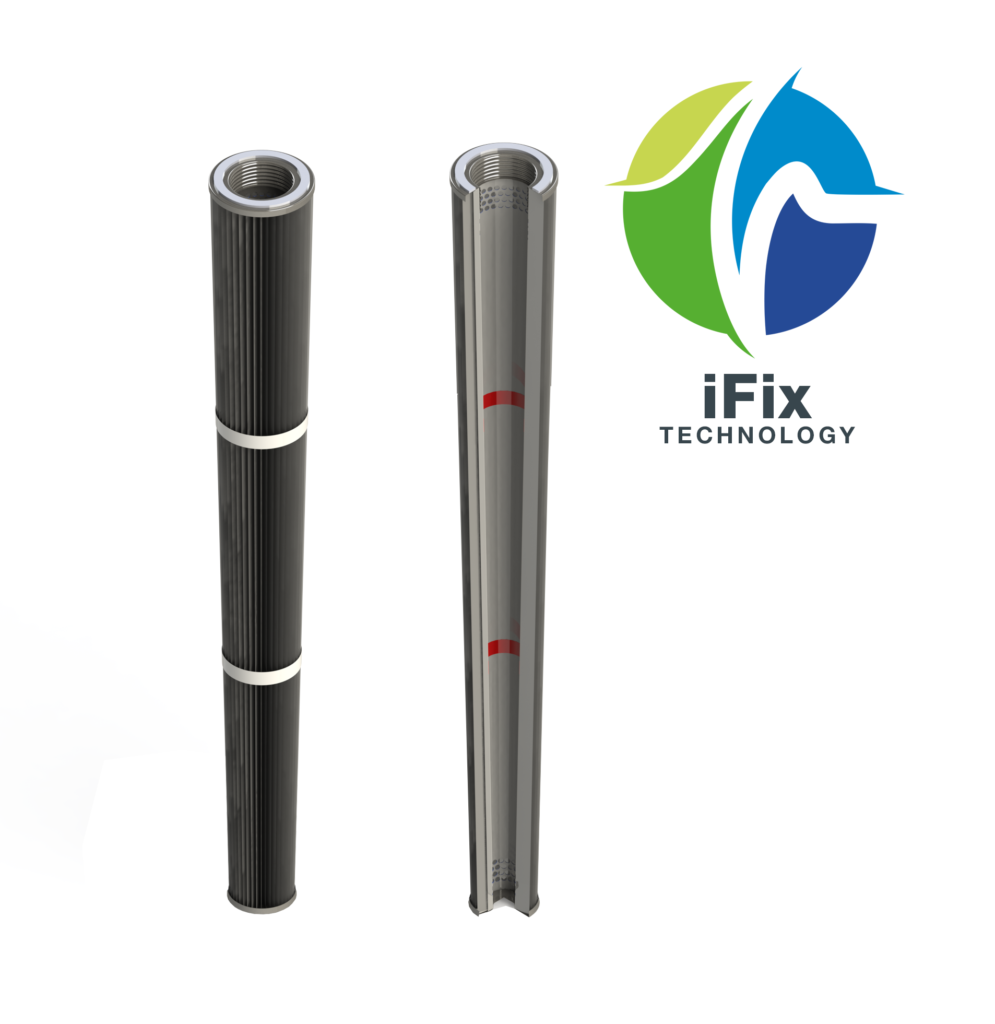

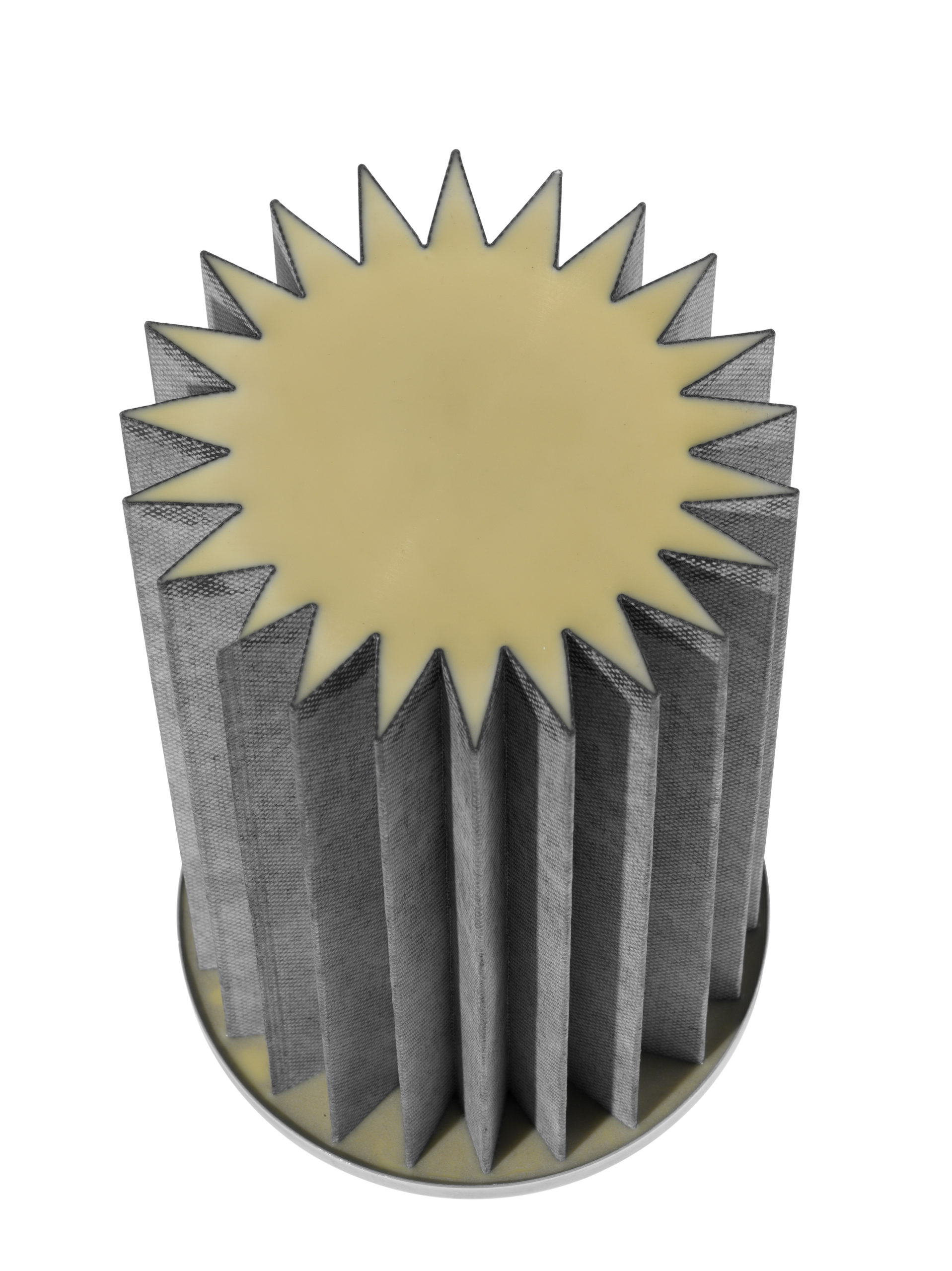

The new innovative star-pleated FGI dust filter elements with iFix technology are used to separate finest particles from gases. The dust-laden gas flows through the filter element from outside to inside and exits through the upper open end plate. The built-up filter cake is cleaned off gently and efficiently by means of jet pulses or a rotating air nozzle.

The FG iFix system replaces conventional pleat stabilization systems with banding on the product side (raw gas side). This guarantees no deposits on the outside of the filter element and completely excludes the entry of foreign substances into the product and prevents 100 % contamination. Especially when membrane filter materials are used, the FG iFix technology solves long-standing problems on the market. The users benefit from a better functionality without product deposits on the band.

High separation efficiency, economical product recovery and compliance with all safety and environmental requirements are ensured. Our FGI dust filter elements are extremely durable, require little maintenance and convince both economically and ecologically.

Conventional technology (left) and new FG iFix technology (right)

The advantages at a glance:

Filtration Group Industrial’s leading expert know-how and state-of-the-art production technologies stand for efficiency and proven manufacturing based on innovative technologies for air pollution control.

Source: Translation for German Magazine Schüttgut & Prozess, Aus der Praxis für die Praxis, No.4/2020, original article