2020-09-08

The patent is the most traditional and technical among the industrial property rights. It is not easy to obtain patent protection for material patents or processes. As the inventor of innovative components in the field of air pollution control, Filtration Group Industrial offers performance-optimized filtration components for maximum efficiency based on years of practical experience and extensive development trials.

Patents are the pulse of technological progress, the heart of every innovative company – and thus of enormous economic importance. Are you looking for a cost-effective and extremely effective pressure surge cleaning system for filter elements? Do you need an all-round solution and want to save money at the same time?

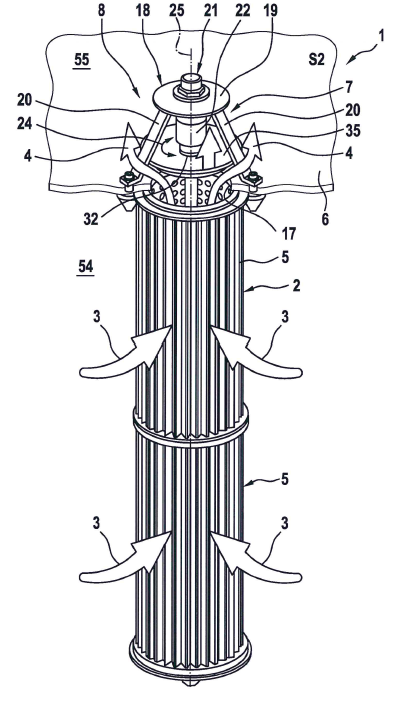

The Multijet nozzle cleans the filter cake very efficiently due to its optimized design and reduced noise level. The special geometry of the nozzle arrangement and the targeted air discharge from several openings with a special angle is patented and does not allow any reproduction. In combination with the distances tested and recommended by us, compared to conventional impulse jet processes, a significantly improved air distribution and cleaning of star-pleated banded filter elements (conical or cylindrical) over the entire length is given. In addition, more secondary air is entrained and thus the cleaning result is further improved.

The rotary air nozzle forms an economical all-round solution for star-pleated conical or cylindrical filter elements. The service life of the filter elements can be significantly increased by a very efficient and gentle cleaning. During the filtration phase, the baffle plate is pushed upwards by the flow. Dust particles are deposited on the filter element surface and a filter cake is formed. The cleaning impulse pushes the baffle plate downwards and removes the filter element from the filtration flow. At the same time, the rotating wing of the rotary air nozzle is set in motion by the nozzle bores and the filter cake is cleaned by the fine compressed air jets and the simultaneous shaking movement in the filter element folds. The cleaning process is quieter and more effective than conventional pressure pulse cleaning and is many times more effective, especially when critical dusts are involved. The dust disk used is triple patented and a replica is protected!

Through inventions and patents, Filtration Group Industrial secures the technical advantages for its customers and the technological edge for itself. Filtration Group Industrial remunerates its inventors appropriately under the Employee Invention Act.

Reinhard Wierling

Head of Lab & Testing