2020-07-07

FILTRATION GROUP OFFERS EFFICIENT BILGEWATER DEOILING

Whether container ship, oil tanker or freighter: bilgewater accumulates on every ship. This leads to a considerable disposal problem, because before the bilgewater can be discharged into the sea, this explosive mixture must be intensively treated in accordance with the requirements of the International Maritime Organisation (IMO).

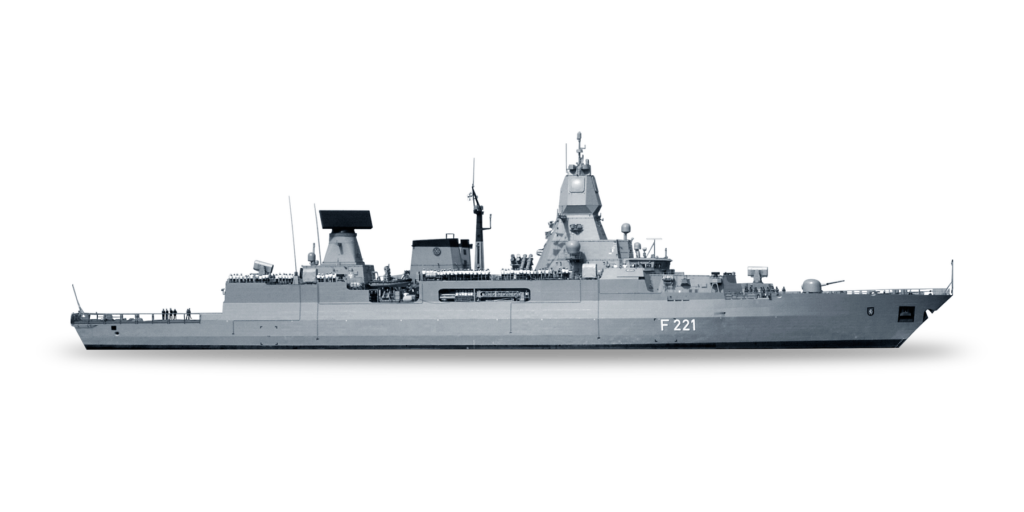

50,000 HP, MORE THAN 400 KM RANGE, MORE THAN 1,000 TARGETS

The navy owns a total of three Sachsenklase frigates. They are designed as multi-purpose ships for convoy protection and sea space control and are supplied by ships of the 3 units “Berlin, Frankfurt am Main as well as Bonn” of the Einsatzgruppenversorger (EGV) on the high seas. They extend the sea endurance of the frigates, whose main focus is on air defence: With their SMART-L radar, a single Sachsenklasse unit can, for example, monitor the airspace over the entire North Sea. The Sachsen Class radar is capable of detecting more than 1,000 targets simultaneously. Thanks to its good communication system with radio and satellite links, the Sachsen-Class is also capable of guiding several other warships simultaneously. The Sachsen-Class helicopters are used for long-range submarine hunting.

THE CREWS

The Sachsen-class frigates are the most personnel-intensive in the fleet. The regular crew consists of 236 soldiers. If helicopters are on board, 18 naval aviators are added. The home port of the frigates is the naval base Wilhelmshaven. Filtration Group is the sole supplier to have a permit under water law to discharge and introduce substances (including waste water) into surface waters. Following the dissolution of the Warsaw Pact, Wilhelmshaven, located on the North Sea, is a favourable location for the new international tasks and missions of the German Navy.

THE CURRENT FRIGATES

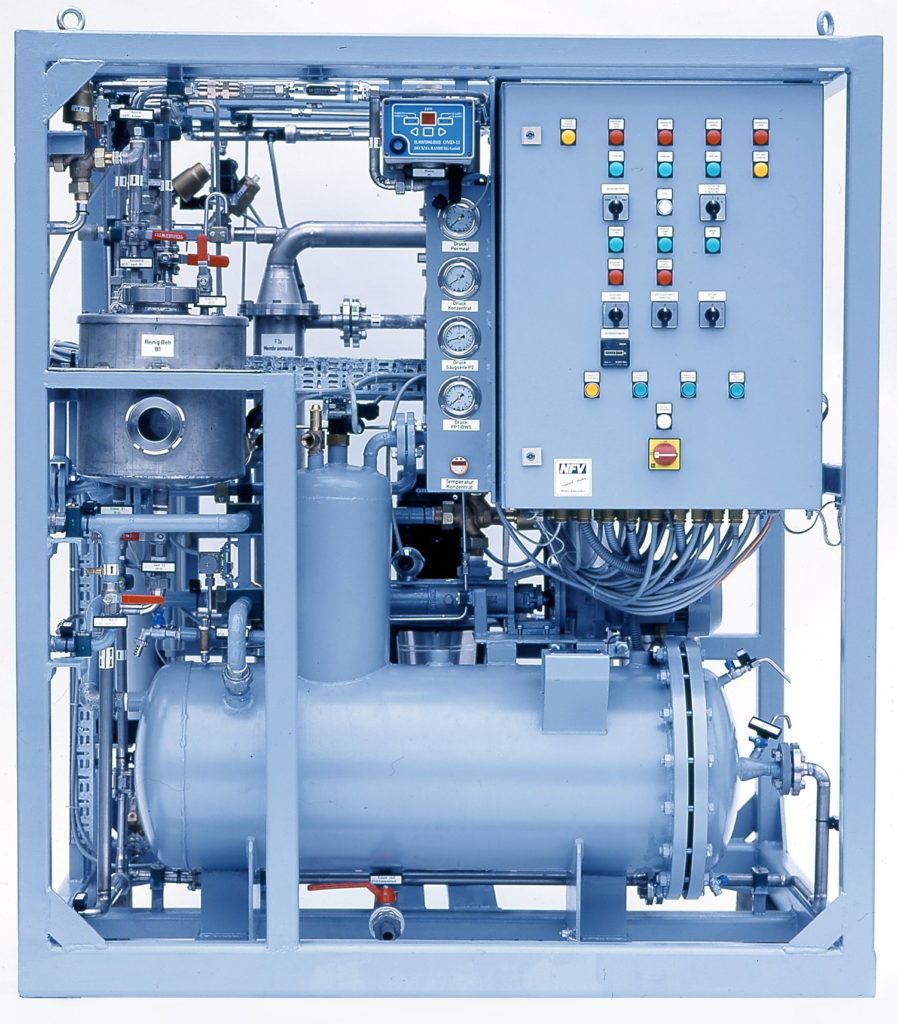

MORE THAN 30 YEARS EXPERIENCE IN THE MARINE

With more than 30 years of experience, Filtration Group offers efficient and economical systems for bilgewater deoiling. Already in 2010, Filtration Group was able to supply membrane filtration deoilers on frigates of the former “F124 Hessen” to replace systems of some market competitors. An environmentally friendly and economical disposal of the bilgewater generated during ship operation could not be ensured with the systems of the competition. The disposal of bilgewater is associated with high costs in the home port and especially abroad. Here, up to 1,000 € per m³ have to be paid. The building regulations stipulate a de-oiling capacity of at least 8 m³ per day for ships of this size. In the event of leaks, accidents or maintenance work, the amount of bilgewater produced can be considerably higher. The plants of the market companions reached here under optimal

conditions max. 4.8 m³ per day. The replacement of the plant was carried out by an authorized repair yard and was accompanied by the service team of the Filtration Group. The FG bilge water separators were of type MPS MF 0.5, type-tested by Germanischer Lloyd and approved according to IMO-Marpol Resolution MEPC.107/49. The nominal capacity of the system, which operates according to the cross-flow principle, is 500 l/h. The systems are designed for an operating time of at least 20 hours per day.

CHALLENGE BILGEWATER DEOILING

Bilgewater results from leakages, from the dewatering of settling and sludge tanks and from the discharge of various cleaning processes. The bilgewater collects in the so-called bilge in the lower part of the hull and can contain salt water, cooling water, fuel and lubricating oil, soot and dirt particles. These impurities and pollutants must never be allowed to enter seawater. The residual oil content of max. 15 ppm permitted for bilgewater to be discharged can be guaranteed without any problems today. However, the development does not stop there and so worldwide ever stricter environmental protection conditions must be observed, e.g. NSA (National Special Areas) and PSSA (Particularly Sensitive Sea Areas). So-called “Green Ship” or “Green Harbour” requirements also demand even more efficient deoiling systems with residual oil contents <= 5 ppm.

INFO

The de-oiling systems and the oil alarm monitor are approved according to IMO Resolution MPEC.107(49). Filtration Group bilge water separators also meet the requirements of all major classification societies.

SPECIALISTS FOR COASTAL AREAS

These are the ships of the K130 class, the corvettes of the Brunswick class of the German Navy are state-of-the-art, especially in ship technology as well as weapon and command systems. Many of the systems on board are automated, important components are multiple. Thanks to stealth properties, corvettes are difficult to locate. They can use helicopter drones. Main weapon of the corvettes is missile RBS15, suitable for sea and land targets. The German Navy specialists are also equipped with membrane oil separators from Filtration Group.

CLEAN WATER IN TWO STAGES

The bilgewater separators clean the bilgewater quickly and reliably from impurities and pollutants in two stages: In the first stage (MPS) the phases water, oil and solids are separated. In the second stage (MF), the safe and permanent separation of finest oil droplets >= 1 µm (emulsion/dispersions) takes place.

Already in 2000, the sail training vessel “Gorch Fock” was the first ship in the navy to be equipped with a membrane filtration de-oiler and has completed approx. 30,000 operating hours since commissioning. Numerous projects have been successfully implemented in the Navy worldwide, e.g. in the Algerian, Turkish and Brazilian Navies. Filtration Group will continue to prove its competence in this field in the future and has already received design approvals for another six ships of tender class 404 to be equipped with FG membrane filtration separators.

Birger Hahn

Market Segment & Key Account Manager Marine