2020-04-22

Initial Situation

Modern tile adhesive consists of cement, sand and various additives, i.e. so-called additives. For the development of tile adhesives the different raw materials are weighed in as powder in certain quantities and mixed homogeneously. Then the processing properties are tested on a sample surface and the adhesive is checked for its suitability for craftsmen. In addition, various tests are carried out in the laboratory, e.g. the adhesive tensile test, which is carried out after various stresses such as wetness or frost. Using a strip of mortar, the deflection and thus the flexibility of the adhesive are tested. During the industrial production of the tile adhesive, the different raw materials are mixed together and filled into bags.

Challenge

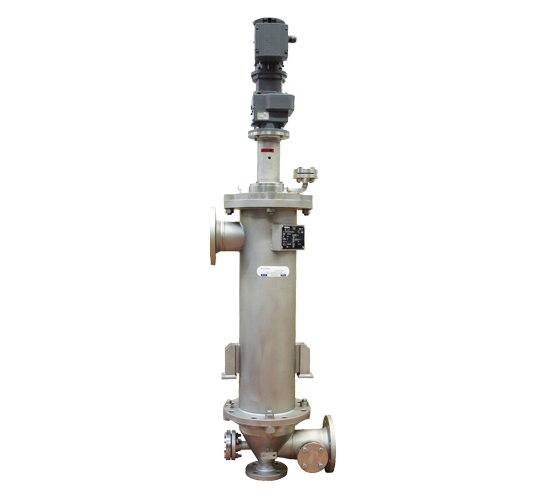

Our customer is part of a globally active specialty chemicals company. Under this brand, solutions in the field of bonding ceramics and floor coverings for professional processors are offered. The range includes tile adhesives, flooring adhesives, jointing and filling compounds. In the manufacturing and production process, the adhesives were previously

filled via simple filter bags. Here there was a technology-related high consumption of filter bags and, due to the nature of the product, also a corresponding product rejection. The manual work involved in changing bags is not significant.

Technical Data

Solution Statement

Customer Value