2019-10-14

Initial Situation

Our customer is part of the global structure of a large food discounter. In different departments they produce bakery products as well as ice cream. Our customer has two large production lines for the production of doughnuts. These are deep- fried with edible oil during the process. During the frying process particles of the doughnuts (sugar, dough) are remaining in the oil. The oil is used in circulation and is reheated in heat exchangers. If the particles are too big, they can block the heat exchangers and cause massive cleaning efforts. Furthermore the lifetime of the oil is reduced if the particles are not removed.

Challenge

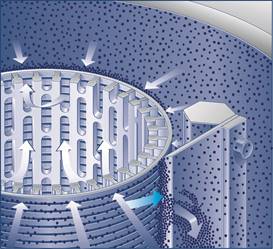

The oil to be filtered flows from the inside to the outside through the filter element. This causes problems with the removal of the particles so that the filter had to be opened frequently and cleaned manually. During filtration, the oil has a temperature of approx. 170 °C, which means there are risks and dangers for employees and the environment. If the filter were to be opened, the oil would spread. Filtration Group has created a dust connection with two valves and a pipe in between for this application. When the differential pressure is achieved, the filter is cleaned and the upper valve opens. Then the lower valve opens and the oil can flow off with great pressure.

Technical Data

– Temperature: max. 180 °C

– Viscosity: 5 – 10 mm²/s @ 170 °C

– Product: cooking oil

– Particles to be separated: sugar and dough particles

– Flow rate: 49 m³/h

Solution

Filtration Group uses a FG automatic metal edge filter type AF 7383 using two filter elements connected vertically. The filter housing is in stainless steel. Thanks to a control bos with level gauge and alarm function industrial processes have an additional level of safety for people and the environment. Customer gradually increases the concentration of particles to be removed from the oil circuit to reduce the loss of usable oil. Cleaning of the filter element starts without opening the valve during each cleaning cycle when differential pressure is achieved.

Customer Value

Due to the filtration process of our automatic filter customers save costs by reducing loss of oil, reduced cleaning of heat exchangers and less spare parts used. A working filter system that automatically cleans itself minimizes less manual handling.

Reduction of downtime:

Our FG automatic metal edge filter keeps the oil circuit clean and removes particles that could block the heat exchanger.

Possible multiplication targets:

Big industrial producers of bakery products using any kind of oil