Industrial Air

Filtration Group Industrial ensures clean air in the work space

The broad portfolio of air filters provides solutions for all applications involving gases, dust and debris that need to be extracted from the working room. Innovation power and decades of experience make Filtration Group Industrial filter elements a perfect combination of advanced technology and proven quality. The high-quality air filters make an important contribution to the protection of employees and equipment and increase the productivity of processes, which would be strongly affected by dust and dirt.

Filtration Group Industrial (formerly MAHLE Industriefiltration GmbH)

The solutions offered by Filtration Group Industrial (formerly MAHLE Industrial Filtration GmbH) stand for high-performance, long-lasting and efficient modules and components in the area of air purification. These well-established filtration solutions ensure interrupted and efficient operations of your equipment and facilities for more than 50 years now.

Explore more

Clear Edge Filtration CFE GmbH

For over 30 years, Clear Edge filtration has been manufacturing flat, pleated filter cartridges, called compact filter elements (CFE™). Clear Edge Filtration has provided products and services to a wide range of customers in the areas of mining, tunnel construction, laser cutting and liquid painting as well as application areas for dedusting.

Contact

We’re happy to help.

Just contact us.

Special solutions

Filtration Group offers all filter systems and separation systems as customized solutions. Our experts will be happy to work with you to find the version that best meets the specialized requirements in your work environment.

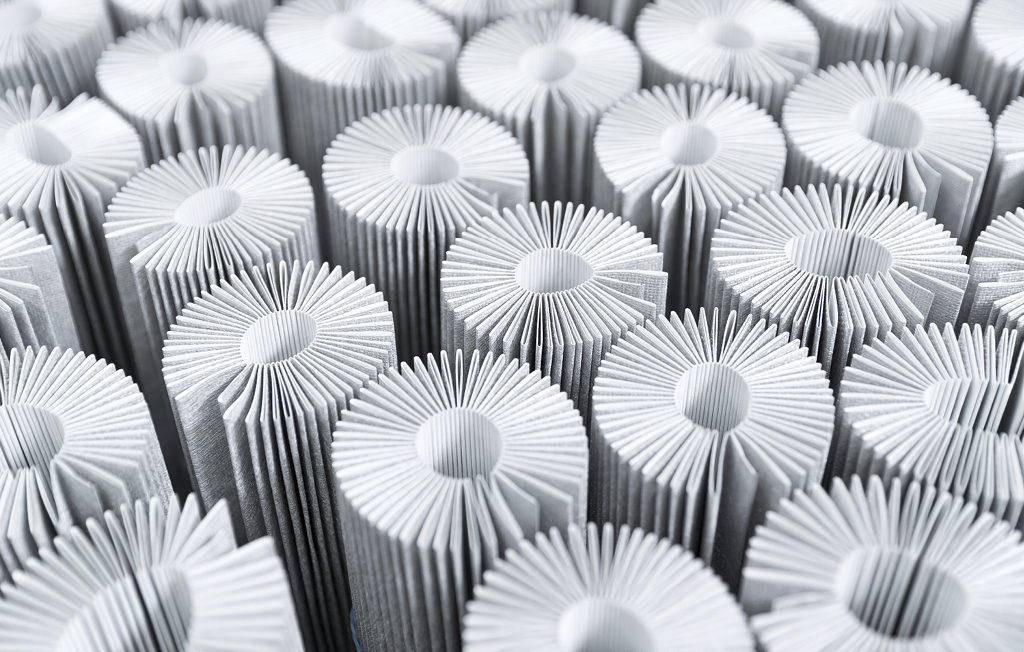

DEDUSTING FILTER MEDIA

DEDUSTING FILTER MEDIA Star-pleated FGI dust filter cartridges are used for separation of smallest particles from gases. The dust-laden gas passes through the vertically mounted filter cartridge from the outside to the inside and exits through the top open end cap. Optimization efforts regarding flow and strength have led to the conical element shape. The cleaning of the filter cartridges using the extra-quiet FGI multi-jet nozzle works much more effectively than with conventional nozzles. The improved cleaning behavior compared to cylindrical filter cartridges and the more favorable flow conditions result in up to 30 percent better performance of dedusting equipment.

Star-pleated FGI dust filter cartridges are used for separation of smallest particles from gases. The dust-laden gas passes through the vertically mounted filter cartridge from the outside to the inside and exits through the top open end cap. Optimization efforts regarding flow and strength have led to the conical element shape. The cleaning of the filter cartridges using the extra-quiet FGI multi-jet nozzle works much more effectively than with conventional nozzles. The improved cleaning behavior compared to cylindrical filter cartridges and the more favorable flow conditions result in up to 30 percent better performance of dedusting equipment. Star-pleated FGI dust filter cartridges are used for separation of dust from air and gases in virtually all branches of industry. The consistently high quality of FGI dust filter cartridges is maintained through regular and comprehensive performance inspections of materials that go into production. Application tests are also conducted at our test benches in the development lab and in facilities on site. Products and production methods can then be improved or redeveloped on the basis of these results.

Star-pleated FGI dust filter cartridges are used for separation of dust from air and gases in virtually all branches of industry. The consistently high quality of FGI dust filter cartridges is maintained through regular and comprehensive performance inspections of materials that go into production. Application tests are also conducted at our test benches in the development lab and in facilities on site. Products and production methods can then be improved or redeveloped on the basis of these results. For more than 30 years compact filter elements

For more than 30 years compact filter elements Special dust problems require well-engineered

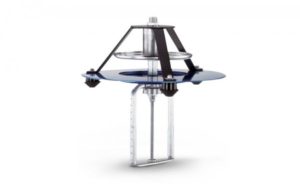

Special dust problems require well-engineered With Filtration Group rotating wings and

With Filtration Group rotating wings and In machining and forming processes in industry – for example in modern machine tools – cooling lubricants (oil or emulsions) are used under high pressure. This allows increased oil mist and emulsions to enter the ambient air. To ensure that the aerosol concentration does not exceed the MWC (maximum workspace concentration) limit values, the cooling lubricant mist must be reliably and continuously extracted and cleaned from the working area of the machines. This is a problem traditional systems are unable to handle.

In machining and forming processes in industry – for example in modern machine tools – cooling lubricants (oil or emulsions) are used under high pressure. This allows increased oil mist and emulsions to enter the ambient air. To ensure that the aerosol concentration does not exceed the MWC (maximum workspace concentration) limit values, the cooling lubricant mist must be reliably and continuously extracted and cleaned from the working area of the machines. This is a problem traditional systems are unable to handle. We combine all our experience in our dedusting units. The interaction of FG filter elements, specially developed cleaning units and optimally designed housings results in our compact dedusting systems. Our standard range starts with small top on filters and extends to large central exhaust systems, if required also with ATEX version. If required, our standard units can also be flexibly adapted to customer requirements in order to achieve the optimum solution for continuous and trouble-free operation with low maintenance requirements.

We combine all our experience in our dedusting units. The interaction of FG filter elements, specially developed cleaning units and optimally designed housings results in our compact dedusting systems. Our standard range starts with small top on filters and extends to large central exhaust systems, if required also with ATEX version. If required, our standard units can also be flexibly adapted to customer requirements in order to achieve the optimum solution for continuous and trouble-free operation with low maintenance requirements.